Breakthrough of technical barriers - Chinese laboratory sealing film counter-current listing.

Date: 2023-12-15 Categories: Industry News Hits: 1805

Basically every laboratory will use a humble product - laboratory sealing film, also known as paraffin sealing film.

For such a small thing, the Chinese laboratory basically uses imported products, parafilm or brand products, why is there no Chinese alternative products?

The first is the technical blockade: the imported laboratory sealing film started early, the product has been tested by the market, the data tends to be mature and stable, and the technical confidentiality is very strong.

Secondly, market recognition: imported laboratory sealing film, especially parafilm, has not had a strong competitor for many years, has a high market share, and has a high degree of customer recognition from product quality and use habits, and even has a certain dependence.

Finally, supply chain and distribution network: After years of customer accumulation and supply chain creation, imported sealing film products have a better supply chain and distribution network than the latecomers, so as to occupy a more favorable competitive position in the market.

So, does the Chinese sealing film have the ability to break through the foreign technical blockade and perfectly replace the imported brand of sealing film products?

There is.

Recently, biofount, a Chinese company in the field of biological consumables, launched a replacement for PM-996 sealing film product (waxfilm). From the data and the feedback of scientific research users, it is not inferior to imported products.

The experimental sealing film mainly has the following requirements, and this Chinese laboratory sealing film waxfilm has been able to achieve similar or even exceed the imported products.

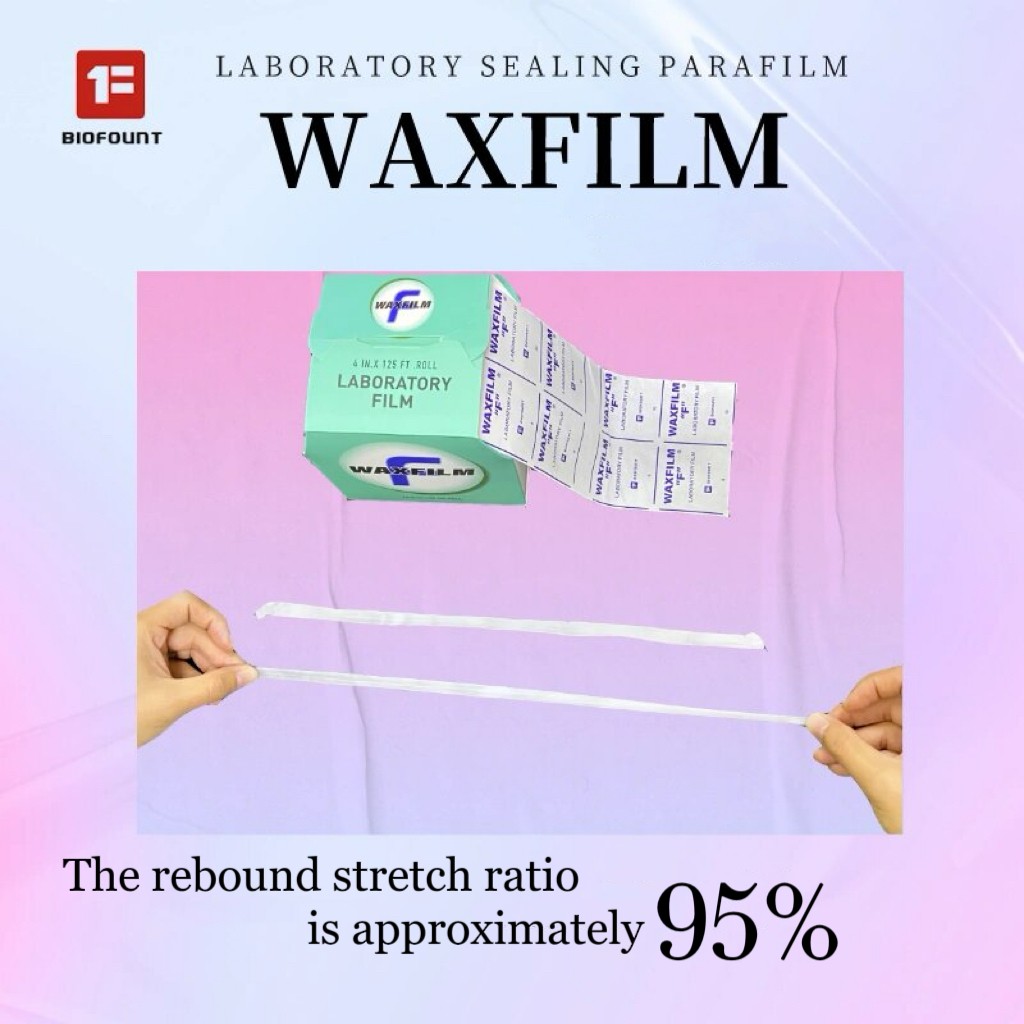

Toughness and ductility: In order to adapt to the edges of different containers in the laboratory, it is necessary to have a certain ductility and toughness, and waxfilm completely exceeds the imported products in these two aspects - more than 4 times the stretch, and it is not easy to rebound (rebound tensile ratio of about 95%).

The role of conventional reagents: the laboratory sealing film must be able to withstand the erosion of conventional laboratory reagents, such as acid and alkali, potassium permanganate, etc., and the performance of these data of waxfilm is almost no difference with imported products.

Low temperature tolerance: Some laboratory supplies need to be refrigerated or even frozen after being sealed by sealing film. The ductility, toughness and tightness of waxfilm barely change after freezing at -80℃, while parafilm has become hard and brittle under the same conditions.

Biocompatibility: ensures that the film material is non-toxic and will not interfere with the integrity of the biological sample.

Uv stability test: Assess the film's resistance to UV radiation to ensure it will not degrade or be exposed for long periods of time.

Of course, Chinese brands still have a long way to go, have to admit that there is a certain gap with imported products in the manufacturing process, we must also face up to the gap, catch up, similarly, as the product use end, we should give Chinese brands some opportunities and incentives, I believe that Chinese brands will not let us down in the end!

WAXFILM - 2IN*125FT

WAXFILM - 2IN*125FT  38m Waxfilm

38m Waxfilm  WAXFILM - 4IN*125FT

WAXFILM - 4IN*125FT  Cell Counting Chamber

Cell Counting Chamber  Cell Counting Chamber

Cell Counting Chamber  WAXFILM 1IN*125FT

WAXFILM 1IN*125FT